Terrazzo Types

Terrazzo can be classified into 2 broad categories based on its type of binder: cementitious and resinous. Originally, terrazzo was a cementitious material, and from the 16th century until today, cement terrazzo has provided a beautiful and durable floor finish. There have been many innovations in cementitious terrazzo, and today it takes a variety of forms. Examples of cement terrazzo systems are:

- Monolithic terrazzo

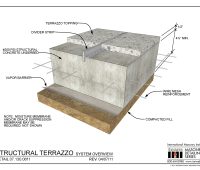

- Sand cushion terrazzo

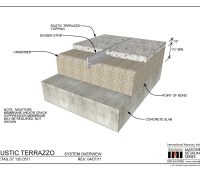

- Rustic terrazzo

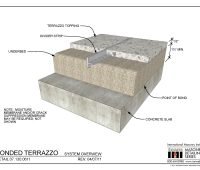

- Bonded terrazzo

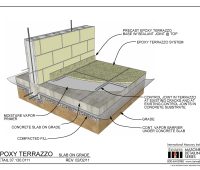

Resinous binders for terrazzo were developed in the United States in the 1960s, and these systems are credited with sparking a renewed interest in terrazzo due to their ability to overcome certain design limitations like color and thickness. In contemporary construction, epoxy terrazzo dominates the terrazzo market.

Examples of resinous terrazzo systems are:

- Epoxy terrazzo

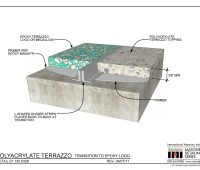

- Polyacrylate terrazzo

- Polyester terrazzo

In addition to the traditional categories of cement and resinous, in recent years, manufacturers of flooring materials and decorative concrete toppings have been developing proprietary systems using cement binders that have been modified to deliver a thinner profile than traditional cement systems, accept a wider range of pigments, and in some cases, are flowable rather than trowel applied.

Substrate Preparation

As with all finishes, the quality and appearance of a terrazzo installation is only as good as the quality of the substrate it’s installed over. Concrete floors typically need some type of remediation to bring their quality in line with requirements of the terrazzo. Here are a few areas to consider.

Moisture Content

Moisture content of concrete is an important quality, especially for resinous terrazzo systems. Unlike cementitious terrazzo, resinous terrazzo is typically vapor impermeable, meaning excessive moisture in the concrete slab won’t dissipate and may cause delamination of the epoxy terrazzo topping. For this reason, moisture readings of the concrete are taken prior to installation of terrazzo. If the relative humidity of the slab is greater than the maximum level recommended by the terrazzo manufacturer, the slab must be allowed to cure longer. Alternatively, a moisture mitigation membrane may be specified that’s compatible with the terrazzo finish.

Elevation

Certain projects require very tight tolerances on finish floor to ceiling heights. For example, the height of a non-adjustable window wall or a retail fixture that spans floor to ceiling may dictate a precise vertical dimension. Terrazzo installers must work backward from the required finish floor elevation to determine the required elevation of the concrete substrate. If the concrete is too high or too low, it must be remediated. Terrazzo contractors and installers are able to reduce the height of concrete by grinding or bush hammering, and if the concrete is too low, they can fill it in with material compatible with the terrazzo. Because the extent of floor preparation is usually not known during design, it’s common for a terrazzo contractor to include unit pricing for floor preparation in their bid.

Flatness

Substrate flatness is important in any thin set terrazzo installation. For thin set installations, substrates are required to be flat within 1/4 inches in 10 feet from the required plane. Thicker installations like sand cushion cement systems don’t hold substrates to this flatness tolerance, since the thickness of the setting bed can be adjusted to conform to the high and low points of the substrate.

Cracks

Cracks in the substrate must be addressed if they are expected to be suppressed and not telegraph through to the terrazzo finish. This is particularly important to bonded systems like epoxy terrazzo, versus floating systems like sand cushion. For a discussion on crack remediation, refer to the crack management section.

Installation

Most of the time, terrazzo is manufactured on site, immediately before it’s placed. The role of the craftworkers spans the entire process from fabrication to installation: they prepare the substrate, place the membranes and divider strips, mix the raw materials, place the terrazzo mixture, rough grind the floor after initial cure, grout the floor as necessary, grind the multiple intermediate stages, polish, and apply sealer. Terrazzo is often considered a work of art, and the installers are the artisans. The quality and beauty of a terrazzo floor is truly dependent on trained and qualified installers.

A typical installation process may incorporate many of these steps:

- Floor preparation: If the substrate doesn’t meet standards for moisture, concrete surface profile (CSP), flatness, or cracks, the terrazzo installers remediate it.

- Membranes: Moisture mitigation, crack suppression, and primer as required.

- Setting bed: In the case of sand cushion terrazzo, a setting bed of sand and cement is floated over the substrate, separated from the substrate by a cleavage membrane or slip sheet.

- Placing the divider strips: Installers lay out the strips per design, including logos, mascots, or other art. The strip layout incorporates control joints based on existing CJs in the concrete, existing cracks, perimeter walls, and other fixed elements.

- Mixing the raw materials: Blending the aggregate of varying materials, colors, and sizes per the specification. The aggregate may be blended on site by hand, or it may be pre blended and bagged prior to delivery to the jobsite.

- Placing the terrazzo: The mixture is transported from the mixing station and troweled in place to the desired elevation, thickness, and finish flatness.

- Rough grind: A pass is made with a floor machine, power trowel, or hand grinders to “take the cream off the top” and expose the aggregate.

- Grouting: The binder material is forced into small voids and gaps as it’s hand troweled as necessary to remediate any chip pop outs or pinholes created by the rough grind.

- Grinding: Typically done in several stages with floor machines, power trowels, or hand grinders, with successively finer grit abrasive pads.

- Polish: The final and finest abrasive is used to achieve the desired finish.

- Sealing: To protect the finished floor, a sealer compatible with the terrazzo is applied.

Every terrazzo job is unique, and most BAC terrazzo contractors are willing to work directly with design professionals to discuss and solve design challenges and to choose a system that is right for the job. Contact IMI for contractor referrals.

Sustainability & Life Cycle Cost

Terrazzo is the most durable of all floor finishes. With basic maintenance, terrazzo can easily last the lifetime of any building, making it the most economic floor finish over a building’s life cycle. There are many examples of 100 year old terrazzo floors in the United States, and some terrazzo floors in Italy date back centuries. Terrazzo frequently makes use of crushed chips of post-industrial or post-consumer recycled glass, marble, granite, onyx, and other materials that would otherwise be relegated to landfill. Many of the binders contain zero VOCs. Finished terrazzo floors do not off-gas. They are non-porous and do not support microbial growth, nor do they allow moisture or mold to accumulate, contributing to a healthy environment for the building’s occupants.

Because the design options for terrazzo are so varied, it’s difficult to quantify the initial installation cost. Terrazzo is a permanent, premium flooring and generally has a higher initial installation cost relative to the initial cost of other flooring materials. With the development of modern thin profile systems with quick cure times, installation time is quicker than ever, saving on initial cost compared with traditional thick set systems. A simple layout and single color represents the least expensive option, and it may be surprisingly competitive against other finishes. Even with elaborate designs, when maintenance and replacement costs are considered, terrazzo can have lower life cycle costs than most other materials.

Non-flooring and Prefabricated Elements

Terrazzo isn’t limited to poured-in-place flooring applications. Many other interior elements, both horizontal and vertical, lend themselves to terrazzo finishes, especially when they match or complement the terrazzo floor. It’s frequently desirable to carry the terrazzo floor a few inches or more vertically, up the adjoining walls, to form a base. Terrazzo base can be poured in place, or it can be precast in long sections and field-applied. There is generally a divider strip in the floor at or near the base, serving as a perimeter movement joint.

The terrazzo returns up the wall with a slight concave profile, easily mopped and maintained, and perfect for discouraging the buildup of dirt, debris, or unhealthy organic material. Terrazzo stairs are another element naturally extending from a terrazzo floor. Stairs can vary in design and can be made of terrazzo treads only, terrazzo treads and risers, or even terrazzo treads, risers, and stringers. Each of these elements can be precast or poured in place. Terrazzo makes beautiful and functional countertops and vanities. Whether precast or poured-in-place, terrazzo counters are sanitary, stain-resistant, and easy to clean. Terrazzo can even go vertical. It’s been used successfully on walls, wainscots, column covers, planters, even ceilings and soffits. Vertical surfaces take precast terrazzo most of the time, although there are plenty of examples of vertical terrazzo being poured in place.